Products

Electrical Power, Safety, & Reliability Solutions

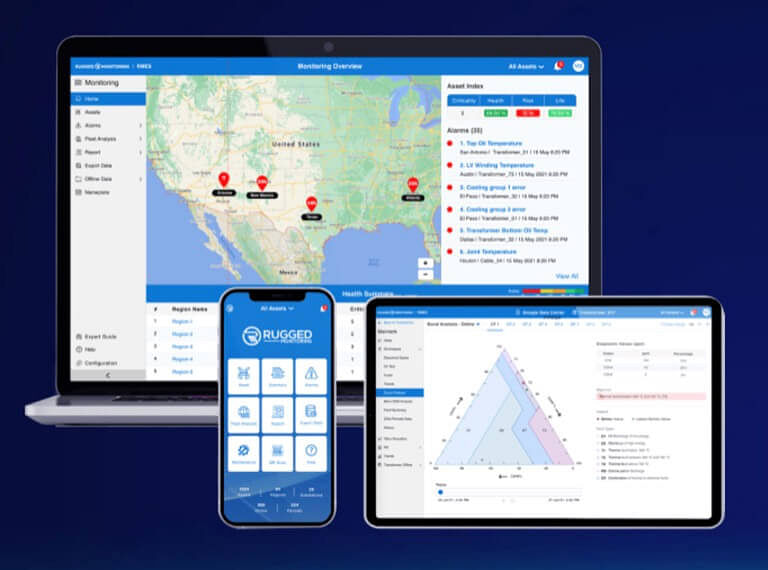

Manufacturing Partners

Availability subject to change, check with your representative for more information

Contact Us

At Pinnacle Power Sales we are focused on providing the best possible service for both our customers and our manufacturer partners.